English

No. 39 Tangning Road, Yunhe Street, Linping District, Hangzhou City, Zhejiang Province

1、A combination of the high frequency technology and a contact roller With a welding width between 1~4 cm, the machine makes a perfect welding.

2、Continuous welding It means a long and complete welding without any stopping while promising an even seam.

3、Instant welding A 3-KVA machine works at a rate of 4 meters a minute, while a 5-KVA one does at 6 meters a minute, hence a rather high production rate.

4、Energy saving Saving workforce by reducing machine handling, and using less power than non-continuous welders by 40~50%.

5、Environment friendly The welding of banners, instead of using of glues, does not generate harms to operators nor pollutions to the environment.

6、A laser positioning system, applied on models ZL3000S/S-805/906/LM, makes easier positioning and operation.

7、Flexible in worktable length For models ZL3000S/S-805/906/LM, a standard worktable is as long as 6 meters, while 3-meter-long modules are available for longer needs

| Availability: | |

|---|---|

| Quantity: | |

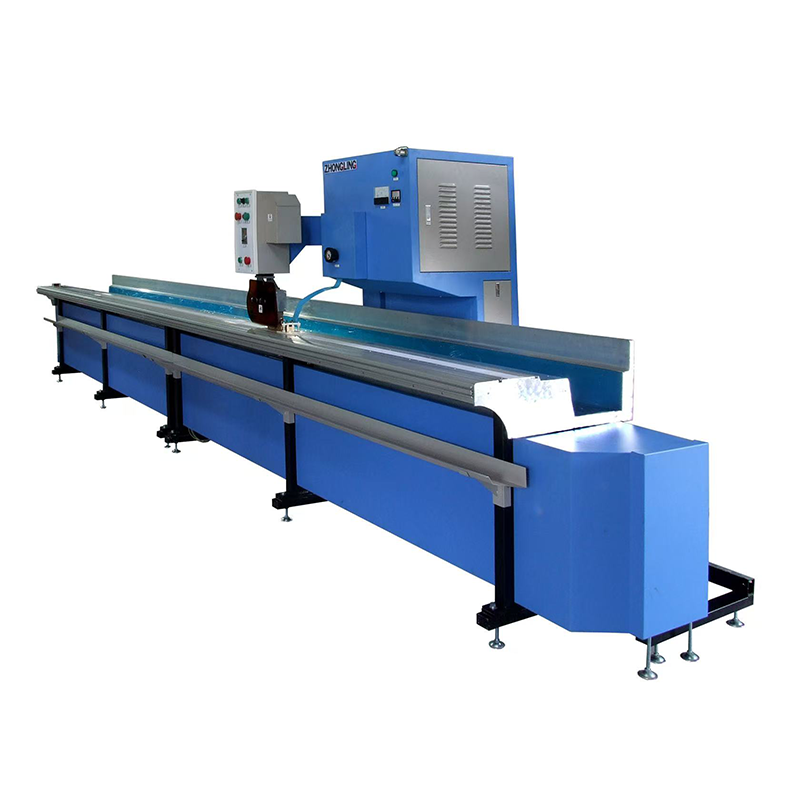

The High Frequency Continuous Welding Machine is a cutting-edge bonding tool designed to redefine efficiency and durability in fabric and material joining. This industrial-grade equipment merges advanced high frequency technology with user-centric design, making it a go-to choice for manufacturers working on outdoor gear, industrial coverings, and storage solutions. Unlike traditional stitching or gluing methods that often fail to withstand harsh conditions, this welding machine creates seamless, long-lasting bonds that resist wear, water, and environmental stress. Whether you’re producing tents for outdoor events, awnings for commercial spaces, or water tanks for storage, the High Frequency Continuous Welding Machine delivers consistent performance that elevates product quality and production reliability.

Combining high frequency technology with precision-engineered contact rollers, the machine produces flawless seams that eliminate gaps and weak points. The controlled welding process ensures uniform bonding across every inch of the material, making it ideal for applications where durability is non-negotiable.

The core strength of this continuous welding machine lies in its ability to work without interruptions. It streamlines large-scale projects by maintaining a steady workflow, eliminating the downtime associated with batch processing or manual bonding methods.

Designed with sustainability and cost-saving in mind, the machine reduces labor requirements through simplified handling. It also operates with significantly less energy than conventional welders, lowering operational costs while minimizing environmental impact.

By replacing harmful glues and adhesives with high frequency welding, the machine ensures a safe working environment for operators. It produces no toxic fumes or chemical waste, aligning with modern green manufacturing standards.

Selected models feature an integrated laser positioning system that simplifies material alignment. This intuitive feature reduces human error, speeds up setup time, and ensures consistent results even for complex projects.

The machine’s worktable is built for versatility. Standard configurations offer ample space for most applications, while optional extension modules let you customize the length to accommodate larger or longer materials, from wide tent fabrics to oversized water tank sheets.

The High Frequency Continuous Welding Machine is engineered with performance and compatibility in mind. Its input power is calibrated to balance robust performance with energy efficiency, suitable for both small workshops and large manufacturing facilities. Operating frequency is optimized to deliver consistent bonding results across a wide range of synthetic fabrics and industrial materials. The air cooling system maintains optimal operating temperatures, protecting internal components and extending the machine’s service life. Air pressure requirements are tailored to support smooth roller movement, ensuring uniform pressure for perfect seams every time. Welding width is adjustable to cater to diverse project needs, from narrow bonds for delicate fabrics to wider welds for heavy-duty materials. Voltage compatibility is designed to work with global power supplies, ensuring stable performance in any location.

| Max.input power | 3~5KVA | Air requirement | 6 bar |

| Standard voltage | 220V±10% | Welding width | 10mm-40mm |

| Frequency | 27.12MHz±0.5% | Welding speed | 2-4m/min |

| Cooling mode | Air cooling | Security Certification | CE |

This versatile welding machine excels in a wide array of applications across industries. It’s the perfect tool for crafting durable roof coverings that shield industrial buildings from weather and debris, as well as truck coverings that protect cargo during long-haul transport. Marine and offshore industries rely on it for vessel coverings that resist saltwater and harsh marine conditions. Outdoor gear manufacturers use it to produce high-quality tents for camping, events, and emergency shelters, ensuring leak-proof seams that stand up to rain and wind. It’s also ideal for manufacturing water tanks for agricultural irrigation, residential storage, and commercial use, as well as inflatable entertainment facilities like bounce houses and water slides. Additionally, it’s a trusted solution for creating leak-proof swimming pools for residential backyards, hotels, and public recreation areas.

A: Yes, the machine is designed with user-friendly controls and intuitive operation. Optional laser positioning further simplifies setup, making it accessible for both experienced operators and those new to high frequency welding.

A: Absolutely, the machine’s versatile design works seamlessly with a range of synthetic materials, including canvas, PVC, polyester, and other fabrics commonly used in tents, awnings, and inflatable products.

A: The machine comes with a comprehensive warranty starting from the shipping date, covering manufacturing defects and ensuring peace of mind for your investment.

A: Yes, we offer custom logo printing on both the machine and its packaging. We can also tailor the product to your specific design requirements, including size adjustments and custom color options.